The more common of the two is grind spatter but either can easily be prevented by installing a temporary screen to protect the glass.

The more common of the two is grind spatter but either can easily be prevented by installing a temporary screen to protect the glass.

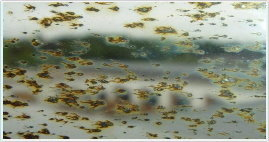

When a grinder is being used on metal, sparks containing very hot tiny red and yellow fragments of the metal fly off at very high speed. On hitting glass they can burn themselves up to a depth of about 0.75mm. The surface of the glass will look pitted with small specs of metal within them and will go brown and stain the glass as the metal rusts.

Weld spatter is caused by the weld slag (gas or mig) which although it doesn’t have the force of grind spatter is much hotter and because of this when it hits the glass it burns itself to about the same depth. Again the surface of the glass will look pitted with small specs of metal within them and will go brown and stain the glass as the metal rusts.

Whilst Clarity Glass Repairs can remove and repair weld and grind spatter it is very time consuming and normally only cost effective for large glazed and bespoke units.

However your glass has been damaged Clarity Glass Repairs can restore your glass saving you up to 80% of the potential costs of the replacement units.

To discuss how Clarity Glass Repairs can help you with your scratched glass and glass polishing requirements please telephone us on 0800 772 0194 or enquire online.